We recognize the environmental risks associated with the semiconductor manufacturing process, and we responsibly manage the use and disposal of materials and chemicals in order to protect the environment and our valued employees.

We aim to achieve high recycling rates in our industry and strive to reduce the amount of environmental pollution created by our operations. We use our own waste management database and focus on proactively controlling the sources of waste, rather than dealing with the issue reactively.

In practice, this involves working with waste treatment specialists, who help us to minimize waste and pollution at source, while also promoting recycling. In the case of waste polyvinyl chloride (PVC), since 2021, all of this material has been recycled through our partnership with a specialized recycling company. We recycled 2.47 tons of PVC in 2023 and no PVC was recycled in 2024 due to the generation of less than 100 kg of waste PVC, and these figures were reported to the Ministry of Environment.

Measurement and targets

We measure the amount of waste we produce through annual EIAs, and regularly set and review waste reduction goals, evaluating our performance against these targets. We try to minimize the amount of waste created by our manufacturing processes by re-using and recycling materials. We outsource the treatment of any unavoidable waste, in order to reduce the impact on the environment.

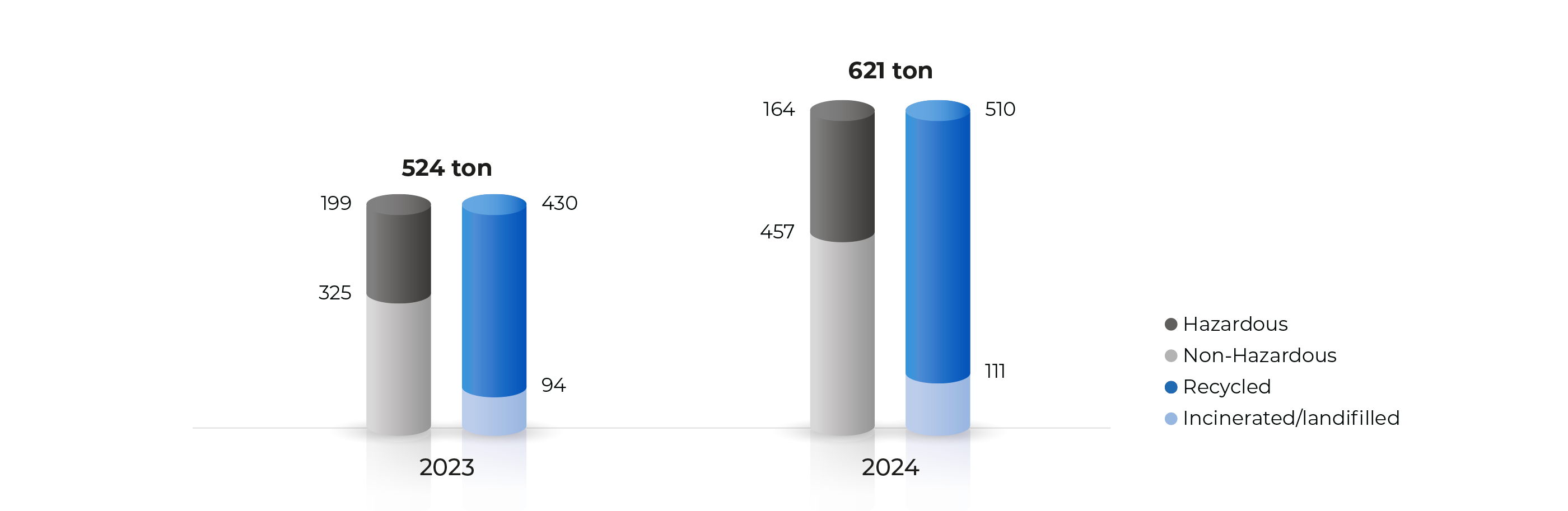

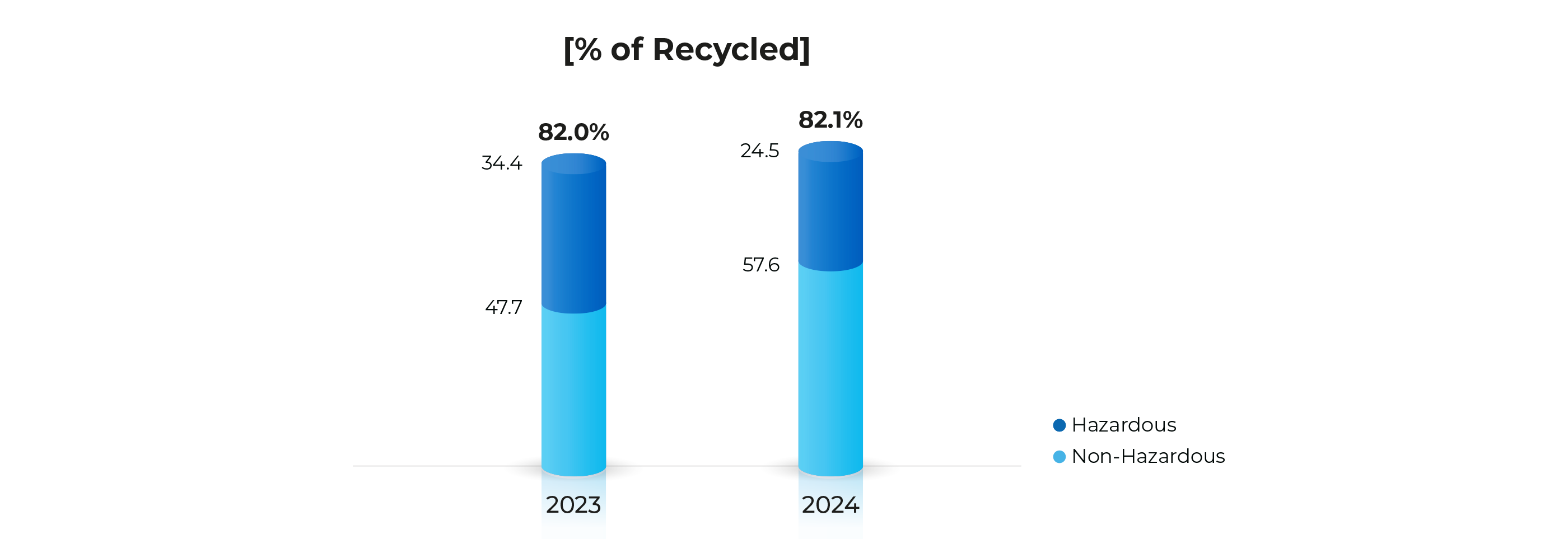

Against the 2024 waste recycling rate target of 45.72% set by the Korean government, we have achieved an 82.1% recycling rate by minimizing the amount of waste that is sent for incineration or landfill.

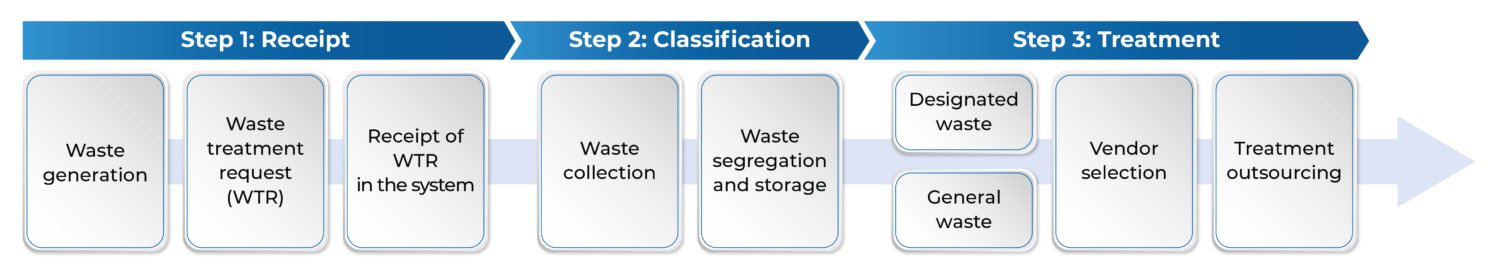

Diagram 3: Waste treatment flow

Diagram 4: Waste treatment results

As shown by the charts above, the amount of hazardous waste we produce annually decreased from 199 tons in 2023 to 164 tons in 2024.